Carlisle TyrFil—We Keep the World Rolling

Carlisle TyrFil has been offering the industry leading tire flatproofing technology for nearly 50 years. Our branded TyrFil Flatproofing product line for pneumatic tires has literally helped to shape and grow the polyurethane tire fill category, commonly referred to in the industry as foam fill, since day one. And today, thanks to our R&D team of scientists who are constantly testing and innovating to build better products, and thanks also to our ongoing partnerships with our valued dealers, OEMS and distributors—we’re proud to be the leading tire fill technology on the globe. TyrFil™ Flatproofing has become synonymous with quality and innovation within the polyurethane tire fill space, and at present, we’re growing faster than ever on the international level.

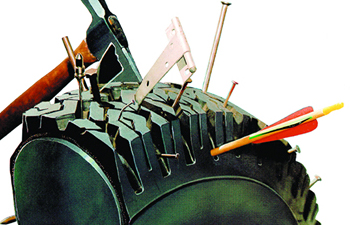

It all began in 1971, when TyrFil™, the world’s first polyurethane tire fill material intended to flatproof tires, was initially invented. Adaptation of the technology quickly grew as Off-the-Road (OTR) heavy equipment operators recognized the many cost-savings and safety benefits of utilizing a tire choice that enabled equipment to remain virtually “flat free” on the job. With TyrFil™, equipment can easily glide over worksite debris—such as rocks, glass, nails and rebar—that would normally pose a huge puncture risk. Tire fill (or “foam fill”) technology improves job site productivity in hundreds of applications including the mining, construction, waste management and materials handling fields.

Today, TyrFil™ Flatproofing solutions can be found in more than 65 countries internationally. The company has manufacturing and production facilities in Tennessee, Ohio, Germany and China—and has processed more than 1 billion pounds of product since our inception. Our vast network combines not only innovation and product development, but distribution, marketing, technical support and customer service—all within a seamless, one stop “shop” that streamlines the way that global dealers, OEMs and customers interface with and adapt our product experience. The ability to offer a single supply chain on an international level—integrating all key components of our manufacturing and end-to-end support cycle—saves both time and money for our valued customers and ensures that our focus remains on promoting operator safety and jobsite efficiency.

Carlisle TyrFil’ marquee production facility, which leads global R&D efforts, is based in Berea, OH, in the U.S. Over the past two years, the company has continued to infuse development dollars into this state-of-the-art production facility. This location has 112,000 square feet in office and manufacturing space on more than 14 acres, with seven full-service laboratory spaces, including a quality control lab and a physical testing lab. Recently, the company invested upwards of $1 million in additional improvements and expansion into this production hub, which is especially well poised to capitalize on the tire and chemical expertise residing in America’s robust Northeast manufacturing sector.

As a leading business unit within the broader Carlisle Performance Materials and Carlisle Companies families, the Carlisle TyrFil division also has further access to world-class polymer scientific development and other international resources that serve and support markets across the globe. Carlisle’s collective operations offer manufacturing capabilities in nine separate production facilities across the U.S., as well as one in Europe and one in China. (The company’s products are found in virtually every commercial and consumer marketplace.)

Presently, Carlisle’s key product lines include the TyrFil™ flatproofing solution (which can be injected into any pneumatic tire to replace air with polyurethane tire fill), TLC Tire & Rim Protection™ wheel conditioner, ReSeal™ tire sealant and Carefree Tire™ micro-cellular polyurethane tires. All of Carlisle’s branded products are formulated to improve safety and increase productivity in demanding OTR applications where equipment reliability is critical—and they are all available globally.

Regardless of the industrial application, Carlisle is seeing strong new opportunities in markets like Southeast Asia (Laos, Cambodia, Singapore, Malaysia, Indonesia, Myanmar, and others) and India, where industry is continuing to develop and grow at a fast pace to remain competitive with other global markets. According to Carlisle TyrFil’ Director of Sales for Southeast Asia, Andrew Elliott: “Tire fill solutions are worth a closer look for anyone in an OTR vehicle operations capacity who is looking to manage bottom-line costs and slow the premature aging of valuable OTR heavy equipment.”

The brand also has a prominent presence in Latin America, Russia, and in the European market, especially the U.K. and Germany, where Carlisle continues to see strong business growth within the construction marketplace that is helping to drive OTR operators toward tire fill innovation as a trusted, flatproofing solution. Adds Mike Arnold, Carlisle TyrFil Division’s Vice President and General Manager: “Carlisle is taking an increasingly important role on the global stage. We’re expanding our international presence significantly and a number of different markets are now becoming aware of TyrFil™ Flatproofing and our related tire care support systems. One of the unique benefits of our product line is that we can help businesses—such as mines, that operate in very remote locations, for example, in the middle of Russia—to maximize their productivity and safety in regions where a tire flat on a large industrial vehicle would present a major obstacle to project efficiency and worker safety.”

As a true global brand in every sense, Carlisle is also strongly committed to delivering a flatproofing solution that is sustainable and eco-friendly. Our TyrFil™ Flatproofing line uses materials that help to reduce the world’s carbon footprint—and our recycling technology supports ongoing, environmentally friendly initiatives to reduce, reuse, or recycle whenever possible. By choosing tire fill over solid apertures tires, OTR equipment operators are helping to keep non-degradable solid scrap waste out of our already overflowing international landfills, which in turn, contributes to worldwide efforts to reduce toxic emissions and protect the many communities we serve across the globe. Carlisle TyrFil’ manufacturing operations create virtually zero waste or emissions. Additionally, as part of our commitment to ensuring a healthier planet, Carlisle has also pioneered a sustainability campaign—partnering with American Forests—called “One Tote, One Tree” that plants a new tree for every tote of product purchased by Carlisle TyrFil’ customers.

These and other programs are just part of the way that Carlisle is growing our impact globally—through new innovation, expanded operations and product adoption, and the responsible championing of efforts that benefit the entire tire, manufacturing and OTR heavy equipment industries. As reflected in our freshly unveiled moniker on Carlisle Tire Fill System’s NEW corporate website, at www.CarlisleTireFill.com, it is with great pride that “We Keep the World Rolling.”

We’d like to send a heartfelt thank you out to all of our valued affiliates, dealers, distributors and OEMs working across the globe. Please continue to keep abreast of new international developments here on the Carlisle TyrFil Blog in the months to come.

Carlisle TyrFil