Telehandler Test – July 2016

BRANDECHO DRAFT v1.0

No More Solid Shock:

A Statistical Case for Why Polyurethane Tire Fill is a

Safer Alternative for OTR Equipment

Contributed Article by Joe Negrey, Vice President of Carlisle TyrFil™

The issue of Whole Body Vibration (WBV), which is the repeated occupational exposure and jarring to the human body from the use and impact of heavy machinery, has long been under-addressed by the Off-the-Road (OTR) equipment industry. It can, however, be a serious issue – costing industrial equipment owners and operators time, money and manpower. When WBV becomes a chronic condition, it is suspected to cause a series of adverse health effects for drivers – including muscular-skeletal and neurological injury, which can be especially prevalent when sustained over a long period of time.

In addition to the negative physical and health effects for OTR heavy equipment operators in the construction, mining, military and industrial fields, the same exposure to constant and severe vibrations can also hasten premature fatigue and wear and tear to the OTR equipment fleet – damaging suspension systems (including axles and other expensive parts) and causing early equipment denigration that is entirely avoidable.

To take a look at the many factors contributing to G-force impact in the OTR industry, it’s first important to understand the dynamics of using filled vs. solid tires – and then consider the results of recent comprehensive field testing conducted by Transportation Research Center (TRC) that demonstrates why selecting polyurethane liquid fill can help mitigate the effects of WBV and “Solid Shock.”

The Role of Solid Shock

When WBV vibration is a result of excessive G-force transmissions from solid aperture tires, it’s what is known in the tire industry as Solid Shock. Surprisingly, little has been written about how and why Solid Shock can wreck havoc on OTR operators and on-the-job productivity. Many industrial equipment owners and operators may not even realize the toll that it can take on their equipment, and most importantly, their human capital.

The phenomenon of WBV can occur when vibration is emitted to the driver while they’re standing, sitting, or reclining. The concept isn’t new. The term occupational seated exposure has been documented in a wide variety of categories ranging from cars, buses, fork-lifts, tractors, trucks and heavy machinery either on or off paved roads (Padden & Griffin, 2002). It also has been determined in the last decade that railway engineers are also vulnerable to significant WBV exposure (Johanning, et al., 2006). While OSHA doesn’t acknowledge WBV impact in its classifications at present, the National Institute of Occupational Safety and Health (NIOSH) has extensively covered the physiological side effects of vibration transmissions to industrial drivers.

In vehicles designed, in particular, to take on rough, rugged and uneven terrain, the physiological effects can be quite significant and may cause fatigue, lower back pain, vision problems, interference with or irritation to the lungs, abdomen, or bladder, and adverse effects to the digestive, and urinary systems. Aside from potential bodily harm to workers, WBV costs companies utilizing heavy equipment thousands, if not millions of dollars, in lost work time due to driver absence during recovery, along with potential workers comp and liability suits.

On the equipment and asset investment side, the cost of Solid Shock can be equally devastating, causing increased equipment damage due to prematurely worn out components as a result of heightened G-force transmission. In addition, the mounting equipment for solid tires is very expensive, and the areas around the holes in aperture tires are more prone to cracking, which increases tire wear and hastens the end of tire life cycle.

The Alternative: Tire Fill

Tire fill, known in the industry as foam fill, is an eco-friendly tire flatproofing alternative to solid tires, that helps to prevent the harmful effects of Solid Shock and it’s unwanted companion – Whole Body Vibration.

With tire fill, polyurethane liquid is pumped into any pneumatic tire to replace air with a resilient, synthetic rubber core that completely eliminates dangerous and costly tire flats in commercial and industrial heavy equipment vehicles. Tire fill can be easily delivered through a valve stem and cures within 24 hours to offer super shock absorption and a smoother flatproofed ride.

Because polyurethane filled tires provide a smoother ride for operators, they provide an optimal solution for the construction, mining, material handling, equipment rental, ground support equipment, waste management, military and agricultural industries. The use of tire fill enables operators to distribute load (carefully matching the properties of the filling medium with the tire and equipment engineer’s intended load deflection characteristics), and this can effectively transmit less G-force to the equipment and operator.

Putting It to the Test: 2016 TRC Field Studies

While proponents of tire fill have long recognized their ability to eliminate Solid Shock and figure this characteristic prominently when selecting tire fill vs. solids (from both an equipment and manpower perspective), my company Carlisle TyrFil™ teamed up with Transportation Research Center (TRC) in East Liberty, OH – a leading, independent industrial equipment field testing consultant – to put this comparison to the test.

The first test, conducted in May 2016, featured a Wheel Loader using 26.5X25 New Firestone L5 Slick with Carlisle TyrFil™ @ 55psi and 26.5X25 New Revolution Solid Aperture tires. Accelerometers were placed on each axle, measuring acceleration in the x, y, and, z axes. One triaxial accelerometer was placed in the cab at the base of the seat. Acceleration measurements were recorded at 100 Hz. A total of ten sensors were placed in vehicle. Runs were conducted over three courses at 5mph and 8mph.

A second independent study, conducted in July 2016, measured and recorded total vibration and WBV levels on a on a Telehandler at a constructed test track facility in Rome, GA. The study examined differences in vibration levels between the use of solid aperture tires and Armstrong tires filled with Carlisle TyrFil™ on a single piece of equipment on the track designed to approximate conditions that might be found at an industrial or construction site.

The Results Say It All

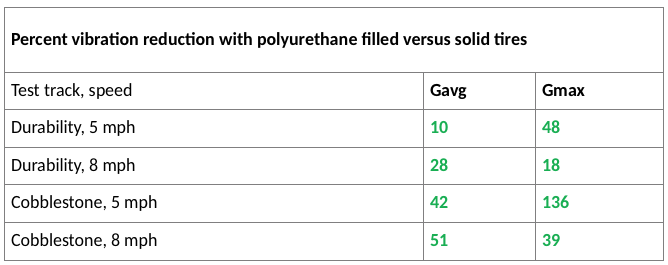

The test results from both field studies were conclusive. In the May 2016 study, test results proved that pneumatic tires processed with Carlisle TyrFil™ outperform solid aperture tires in creating less G-force, which results on average in less equipment stress (36%) and less adverse WBV (Whole Body Vibration) effects (41%) to operators. Specifically, the TRC results demonstrated measurably lower vibration levels in the cabin (floor-mounted accelerometer at the seat mounting) for polyurethane fill tires versus the solid tires on the Durability and Cobblestone tracks. The below chart outlines key findings.

The results were very positive for the vibration reduction on the durability course, in particular, which possessed features that introduced quite severe shocks to the vehicle.

Dr. Helmet Paschold, PhD., CSP, CIH Assistant Professor, Department of Safety Sciences Indiana University of Pennsylvania, added analysis regarding the findings presented by TRC and concurred that the measured cabin Gavg and Gmax values clearly support a claim of reduced vehicle cabin vibration with the use of Carlisle TyrFil™ product in pneumatic tires when compared to solid aperture tires.

In the second independent Telehandler test, conducted in July 2016, indications corroborated the May 2016 Wheel Loader findings. The Armstrong tires clearly presented the lowest WBV values, both r.m.s. and VDV, loaded and unloaded, among the tires both on the cabin floor and seat/operator interface. According to Dr. Paschold, “The WBV differences are not random, but are significant. The data obtained on the cabin floor should be of greatest interest as it discounts the effects of the vehicle seat. Careful selection of an effective properly adjusted vibration-attenuating seat coupled with the use of Carlisle® polyurethane fill in select tires can greatly reduce WBV exposure levels and associated human health risk.”

For the full results of the Solid Shock vibration impact and field studies conducted in May and July 2016, please visit carlisletyrfil.com/no-more-solid-shock/ for additional information.

Conclusion

The findings illuminate the reality of solid aperture tires’ vibration impact on both operators and their equipment, in comparison to polyurethane filled tires, which offer better shock absorption and a more comfortable, safer ride. While any industry can be slow to adopt new standards, tire fill is a technology whose time has clearly come. The data and field testing results are defensible and clear: OTR operators who want to protect their people, profits and equipment investment have a flatproofing alternative that simply makes better sense.

Joe Negrey is Vice President, Carlisle TyrFil™ (formerly ArncoPathway), a division of Carlisle®. Carlisle® manufactures and markets Carlisle TyrFil™, the industry’s leading foam fill and tire flatproofing solution for the past four decades.